Factory Professional Supplier Non

Basic Info.

| Model NO. | MF-1010, MF-1020, MF-1025, MF-1040, MF-4060 |

| Refractoriness | 800-1400°C |

| Diameter | 4-30mm |

| Apparent Density | 180~210kg/m³ |

| Surface Treatment | High Temperature Calcined Wire |

| Usage | Exterior Tiles, Interior Tiles, Friction Materials |

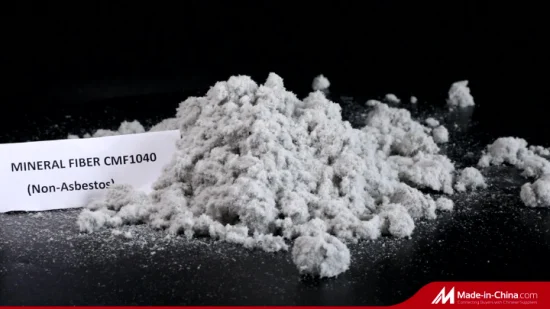

| Color | White |

| Transport Package | PP Bag, Pallets |

| Specification | MF-1025 |

| Trademark | HGS |

| Origin | Hebei |

| HS Code | 68069001 |

| Production Capacity | 5000mts |

Product Description

According to the adjustment of the state administrative policy and the transformation of the automobile friction materials to non-asbestos, our factory introduce advanced technology from Germany and specialized automatic production line of fiber products. The fiber products we manufactured are ideal material which can replace asbestos in friction materials. We have mineral fiber, ceramic fiber, nature cellulose fiber, composite fiber and so on. Brake linings made from our fiber products have many notable features such as braking stably, high temperature properties, little abrasion, low (no)noise and long life. They are very popular in friction materials manufacturers.

Chemical composition

| SiO2 | Al2O3 | Fe2O3 | CaO+MgO | Na2O+K2O |

| 40%-60% | 15%-25% | 3%-7% | 25%-30% | 3%-6% |

Characteristics and applications

Good decentrality, used well in brake linings, and it is suitable for all types of tempering mixer.

Recommendatory dosage:Brake drum:15-35%Brake disc:8-25%

technology indicators:

| NO. | Subject | Technical indicators |

| 1 | The average fiber length | 1.0-3.5mm |

| 2 | The average fiber diameter | 3.0-8.0mm |

| 3 | fiber Distribution | 40#30-40%60#40%-60% |

| 4 | Fiber loss-on-ignition (adjusted according to customer needs) | <1%(800ºC/H) |

| 5 | Content | <3% |

| 6 | Fiber moisture | <1.5% |

| 7 | Fiber density | 0.10-0.25g/cm3 |

| 8 | Fiber density | 0 |