Green Cellulose Lyocell Staple Fiber for Spinning

Green cellulose lyocell staple fiber for spinningAbout YOCELL® fiber From nature Lyocell fiber has a wide range of raw m;

Basic Info.

| Shape | Protein Fiber |

| Raw Material | Extract of Lotus Seeds, Leaves; Wood Pulp |

| Transport Package | PP Woven Bag |

| Specification | 1.0dtex*38mm, 1.25dtex*15mm, 1.33dtex*38mm |

| Trademark | Y&B |

| Origin | China |

| HS Code | 550490 |

| Production Capacity | 50000 |

Product Description

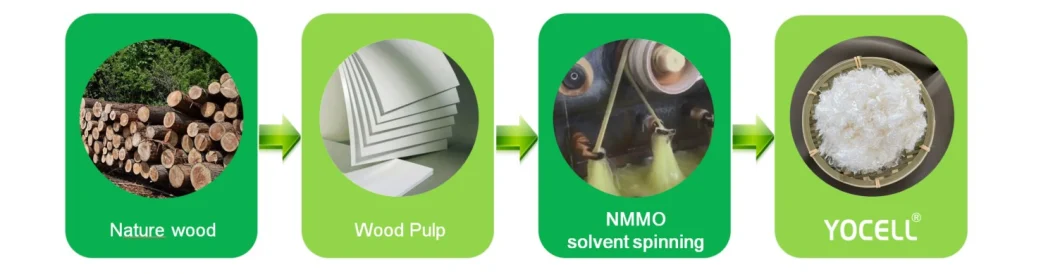

Green cellulose lyocell staple fiber for spinningAbout YOCELL® fiberFrom natureLyocell fiber has a wide range of raw materials, including natural wood, short cotton lint, broad-leaved forest, fast-growing wood, bamboo, straw and so on. Yocell® fiber is a kind of lyocell fiber physically produced from natural wood through NMMO solvent method. It is a pure bio-based regenerated cellulose fiber.

Green & Environmental protection

Yocell® fiber production adopts environmentally friendly closed production process, and all organic solvents are non-toxic and harmless, and can be recycled. Fiber is naturally degradable.High efficiency output

Yocell® fiber production does not undergo any chemical treatment. It has very high production efficiency which only takes 2 to 4 hours from feeding to packaging.Extremely stable and comfortable

Yocell® fiber's fabrics have as good moisture absorption and breathability as cotton, as good drapability as hemp, and as good feel and luster as silk. Its dry and wet strength is much higher than that of viscose fiber, and it is light, easy to wash and easy to dye.Wide range of applications

Yocell® fiber can be blended with cotton, linen, silk, wool, chemical fiber, etc. It has good spinnability and can be used for weaving and knitting. It can also be widely used in non-woven products.

Green & Sustainable production process

Yocell® fiber's raw materials come from nature, the composition is 100% cellulose, which is naturally biodegradable. The NMMO solvent method exceeded the traditional carbon disulfide chemical viscose production process, and the solvent recovery rate is over 99.7%, and the production process is green and pollution-free.

YOCELL® Applications

Home TextileBedding fabric,Pillow & quilt infilling materials

★ Silky and delicate★ Fresh and comfortable

★ Hygroscopic and breathable

★ Bacteriostasis and mite eliminationYocell® fiber is one of the most environmentally friendly fibers, and its excellent properties perfectly meet the needs of home textile products.

Suit, Denim, Children's wear, Under wear…

★ Comfortable, breathable★ Light soft, anti-wrinkle★ High-strength, washable

★ Bright colorYocell® fiber has the comfort of cotton, the toughness of polyester, the warmth and softness of wool, and the soft drape of silk. The production process is environmentally friendly which makes life back to nature.Nonwoven

Hygiene and medical, Facial mask, Wipes, Specialty paper…

★ Efficient and safe★ Excellent performance

Yocell® fiber has properties of natural antibacterial, breathable, moisture absorption and retention. It is a suitable health care material. It can be widely used in medical, nursing, hygiene products, cosmetics and other non-woven fabric fields.

YOCELL® Specification

Flexible production process

Customers can customize various specifications of Yocell® staple fiber and filament tow, including 1.1dtex-3.33dtex * 16mm~102mm...

For different applications, Yocell® can provide different denier, length, fibrillation degree, whiteness and other properties fibers to meet the different needs of infilling, spinning, and nonwovens area.

Fiber Data

| Fiber | Linear densitydtex | Dry strengthcN/dtex | Wet strengthcN/dtex | Dry elongation% | Wet moduluscN/dtex | Moisture regain% | Oil content% |

| Yocell | 1.10~3.33 | ≥ 3.8 | ≥ 3.00 | 10~14 | ≥ 1.5 | 9~13 | 0.2~0.3 |

YOCELL® Cationic modified lyocell fibeCationic modified lyocell fiber

★ Salt and alkali free dyeing

★ Normal temperature dyeing

★ Antibacterial

★ Soft and skin friendlyYocell® Cationic modified lyocell fiber is hydroxyl group grafted lyocell fiber by using our patented technology. The modified fiber has high affinity to anion dyes, and can be dyed in salt free and alkali free reactive dyes, and has high dye uptake rate, which can effectively prevent the problems of high consumption of dye, salt and alkali and high processing cost of traditional dyeing.

The fiber has good affinity to reactive dyes, acid dyes, direct dyes, anionic disperse dyes, pigments, heavy metals, etc., and can be adsorbed in large quantities at room temperature.

It is also has good antibacterial effect after modification, and also has good mildew prevention effect.

The fiber has characteristics of soft feeling like silk and cashmere and skin friendly, which meets the needs of different apparel fabrics.

You may also like

Send inquiry

Send now